Dimensioning

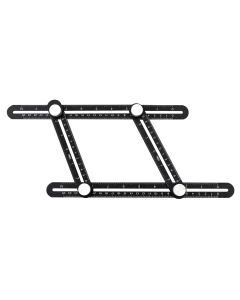

Measuring is the first phase of a project. For three-dimensional components, we recommend the 3D Japanese square, which will allow you to easily measure shapes such as pipes. It has limitations for 45° and 90° angles, the ability to transfer measurements, and plot parallel angles and holes for determining the drill diameter. Precise measurements will be ensured by a multifunctional square consisting of a double-sided ruler and a head with a built-in spirit level. It is also used for making precise 45/90-degree angles, marking straight lines, and drawing parallel lines.

For simple vertical-horizontal and right-angle measurements, an electronic spirit level comes in handy. Emitting a light beam, electronic spirit level will allow you to precisely determine the hanging points of a shelf or frame on the wall. Functions such as a digital display and an audible signal for the desired measurement will speed up the work of the professional and eliminate the risk of measurement error for the amateur.

Clamps

Clamps facilitate the precise joining of two or more components. There are several types of clamps with different mechanisms of action. Carpenter's clamps may differ not only in structure or shape but most of all in their purpose. There are six basic types of carpenter's clamps:

F-type carpenter's clamp - this is the most common type of clamp. One arm is fixed on the guide bar, while the other moves on it. This type of clamp resembles an adjustable French wrench. F-type tools come in two versions: the screw clamp and the automatic clamp. The former one is tightened by a screw or crank, whereas the latter type operates with a pistol mechanism. Automatic clamps can also be equipped with a special sliding mechanism, which improves working comfort by allowing the jaws of the tool to press more easily and quickly against the material being squeezed. Professional clamps with a gripping force of up to 500 kg are based on an eccentric mechanism.

C-type clamp- This type of clamp has a strong, C-shaped cast body. Thanks to the use of a clamping screw, they are characterised by their relatively high strength and resistance to bending. Carpenter's C-clamps are especially useful in welding, drilling, or model making.

Corner clamp - this type of clamp is most commonly used in workshops. To be able to use them correctly, they must be fixed to the table. They enable precise clamping of glued elements at 90°. Helpful for gluing, screwing, and nailing.

Angular clamp - it is very similar to the corner clamp. It also works well for holding workpieces joined perpendicularly.

Tubular clamp - makes it possible to glue together large components, e.g. furniture boards. This is possible thanks to pipes of different lengths.

Strap clamp - designed for squeezing workpieces that are large in volume e.g. chests, frames, furniture, etc. This type of clamp consists of a frame and a clamping strap attached to it (its length may vary depending on the model). Most commonly, strap clamps are used when gluing furniture - e.g. unusual shelves, chairs, and tables.

Cutting

To make the right cut, the tool must be adapted to the type, thickness, and purpose of the wood. For advanced and long-term projects saws, circular saws, or jigsaws will be helpful. For smaller, non-demanding jobs hand saws and axes will suffice, and for manual processing and finishing you will need chisels and sanding papers. Japanese saws are considered to be the most precise hand tools for cutting. They are marked by a flexible blade that facilitates cutting in various planes. The high density of teeth makes cuts more precise.

Axes

Choosing the right axe depends on the intended use. You need to decide whether the axe will be used for chopping, splitting, or hewing wood.

The splitting axe is primarily used for splitting large pieces of wood. It is characterised by a large head with a wedge-shaped design and a long handle. It is a tool that requires a lot of strength, so it is essential that we adjust it to the length of our arm.

The carpenter's axe is designed for hewing wood and will be helpful for minor construction and farm works. It has a straight cutting edge, ideal for planing and carving. The axe's blunt head is made in a way that the hand is as close to the cutting edge as possible, giving full control of the axe.

If you need an axe for different jobs, it is worth choosing a universal axe - for various uses around the home. In terms of size and weight, it is a compromise between a carpenter’s axe and a splitting axe.

An important element to look at when choosing an axe is the shaft. Usually, there is a choice between wooden or composite handles. Ash is said to be the strongest shaft material because of its long and flexible fibres. The advantage of a wooden handle can also be that it is easy to replace when damaged. Fibreglass handles are known for their high resistance to frequent temperature changes, moisture, or mechanical damage. However, if the composite is damaged, then the entire tool must be replaced.

Chisels

The carpenter's chisel allows precise modeling and removing wooden parts.

A chisel is also a traditional tool for sculptors, for whom the handiness and precision of the tool is important. Tools are often offered in sets, as different blade sizes are usually useful for one job. When purchasing, it is worth paying attention to the hardness of the steel (recommended above 60 HRC). The handle, which is usually wooden, should fit well in the hand. Chisels with a two-component handle are also available.

Milling cutters

In carpentry, milling cutters are used for woodworking and decorating, but also all kinds of notches and grooves for construction purposes, e.g. holes for hinges and many others. The tool is often called a modern chisel because it allows one to perform certain operations much faster and easier than with a traditional chisel. It is ideal for rounding corners and profiling the edges of furniture, by giving them a unique shape. The most important element of the milling cutter is the cutter, i.e. a replaceable tip with a blade, which is attached to the mandrel. The cutter moves in a rotary motion and cuts processed wood. Cutters differ not only in shape but also in the material they are made of. Thanks to this, milling cutters can be used to process other materials than wood.

There are two basic types of cutters: socket and shank. The former is the most common because of installation ease. They have a hole through which they are fixed to the spindle of the milling machine. When it comes to shank cutters, it is necessary to have a special shank to which a cutter can be attached without fixing holes. They are divided into five different types, which differ in the construction of their blades. It includes: Straight milling cutters- they are ideal for countersinking, while face milling cutters will allow you to deepen holes. Spiral cutters are also suitable for countersinking but are more robust and ideal for working on hardwood. Profiling router bits are used for making decorative elements. They require high precision and the best equipment. There are also shank cutters for joints, wooden profiles, as well as frames and grooves.

Sawing machines

Every carpenter's workshop is equipped with a precise saw and a jigsaw. Regardless of whether you’re cutting wooden boards, OSB boards, or furniture panels - and on what scale you're doing it - we recommend reaching for the proven GRAPHITE battery tools.

Different blade diameters characterise electric saws. Before choosing an accessory, make sure that it is suitable for working with the specific material. Only in this way will you achieve the desired effect.

Grinders

Sanding is the final element of carpentry work, which serves to even out the usable surface and prepare it for painting and varnishing. For large flat surfaces such as worktops, it is advisable to use a belt sander which, working in a linear motion along the grain of the wood, will sand a large surface quickly and efficiently. Eccentric sanders are more versatile than belt sanders, as they can be used to smooth out both flat, concave and convex surfaces, and they also can remove paint coatings from both wood and metal. The main difference between oscillating and eccentric sanders is the motion of the sanding pad: an oscillating sander makes an oscillatory motion and an eccentric sander additionally performs a rotating motion. This makes it suitable for more precise work.

Drill-drivers

These are some of the most popular and widely used tools. They are invaluable both during a small home renovation and in a carpenter's workshop. When choosing a drill-driver, we should pay attention to parameters such as: power supply - battery, mains or pneumatic, power/voltage, torque expressed in Nm., type of battery used, number of gears, surge or lack of it, motor - brushless or with brushes, grip size 10mm or 13mm

We recommend choosing cordless tools for convenience and with a brushless motor, which does not require changing brushes, which makes it more durable.

Jigsaws

Jigsaws are tools for cutting irregular shapes in wood, such as curves or holes of different diameters. When choosing a jigsaw, it is worth considering the comfortable and well-shaped handle and the low weight of the machine. All GRAPHITE jigsaws have a multi-stage speed control, spotlighting, and dust extraction system that cleans the surface of the workpiece. The choice of a saw blade is also an important aspect. Jigsaw blades differ in terms of the material they are to work on, and what material the blades are made of. When choosing a saw blade we check the teeth, thickness, and width. GRAPHITE saw blades have appropriate numerical and pictorial markings that will help you select the right product.

Heat guns

Heat guns are often used in the woodworking industry to restore furniture, i.e. to remove paint coatings and also to thermally age wood. When choosing a tool, it is important to check whether the device has a multi-stage temperature regulator, because every wood behaves differently when exposed to high temperatures.

Supplementary tools

The choice of abrasive accessories is vast because abrasion is gradual from low grit to higher grit. It is necessary to select the type of abrasive, i.e. grain, for the work. The most suitable for oscillating sanders is corundum, famous for its valued abrasive qualities, but also electro-corundum, ceramic electro-corundum, or silicon carbide. All GRAPHITE abrasive articles are marked with size, gradation, grain, and grit to help you select the product for the extent and type of wood sanding you need.

Auxiliary tools

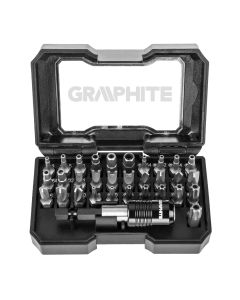

It is also crucial to equip with supplementary tools for carpentry work, e.g. appropriate lighting if you work after dark or need to illuminate the workplace, for example with a spotlight or a headlamp. Bit sets, or hinge or invisible joints assembly kits will also be useful.

Carpenter's essentials

On the market, there are sets of carpentry accessories packed in neat suitcases or trunks. You can also complete your own handy repair kit yourself. We recommend that it includes the following products:

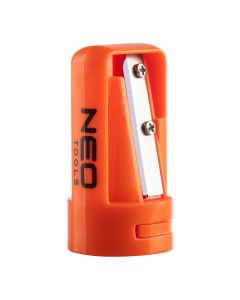

● Technical pencils with sharpener and additional refills. Such pencils have wide graphite, which can clearly mark points on the wood,

● Carpenter's hammer - designed primarily for driving nails. The monolithic construction of NEO carpentry hammers makes them exceptionally strong. They are made of a single steel element. The blunt head was induction-hardened and laser-polished. The two-material handle is covered with an anti-slip layer, which contributes to the comfort of work.

● Chisels, cutters, files - for gouging, modeling, and removing the unnecessary wood layer in hard-to-reach places. It is worth choosing a comfortable handle so that our hand does not get tired during long work. The NEO brand offers comfortable wooden handles or two-component plastic handles.

● Squares, tape measures, spirit levels - a well-marked square, will ensure good measurements at the start of a project. When choosing a product, it is worth paying attention to whether the product has inch or metric graduations.